Motorizing Your Grain Mill

CAUTIONS:

Full Liability And Responsibility For Complying To All Federal, State and Local Safety Standards Is Assumed By Any Person Or Persons Who Modify Or Motorize The Country Living Mill In Any Way.

Full Liability And Responsibility For Complying To All Federal, State and Local Safety Standards Is Assumed By Any Person Or Persons Who Modify Or Motorize The Country Living Mill In Any Way.- Motorized mills should be operated by adults only. The below schematics are merely suggestions that may help you achieve a lower r.p.m. for cooler grinding if you choose not to grind by hand.

- Note: All belts and pulleys not driven by hand should be enclosed.

- All belts and pulleys not driven by hand should be enclosed.

Purchasing our Motorization Kit

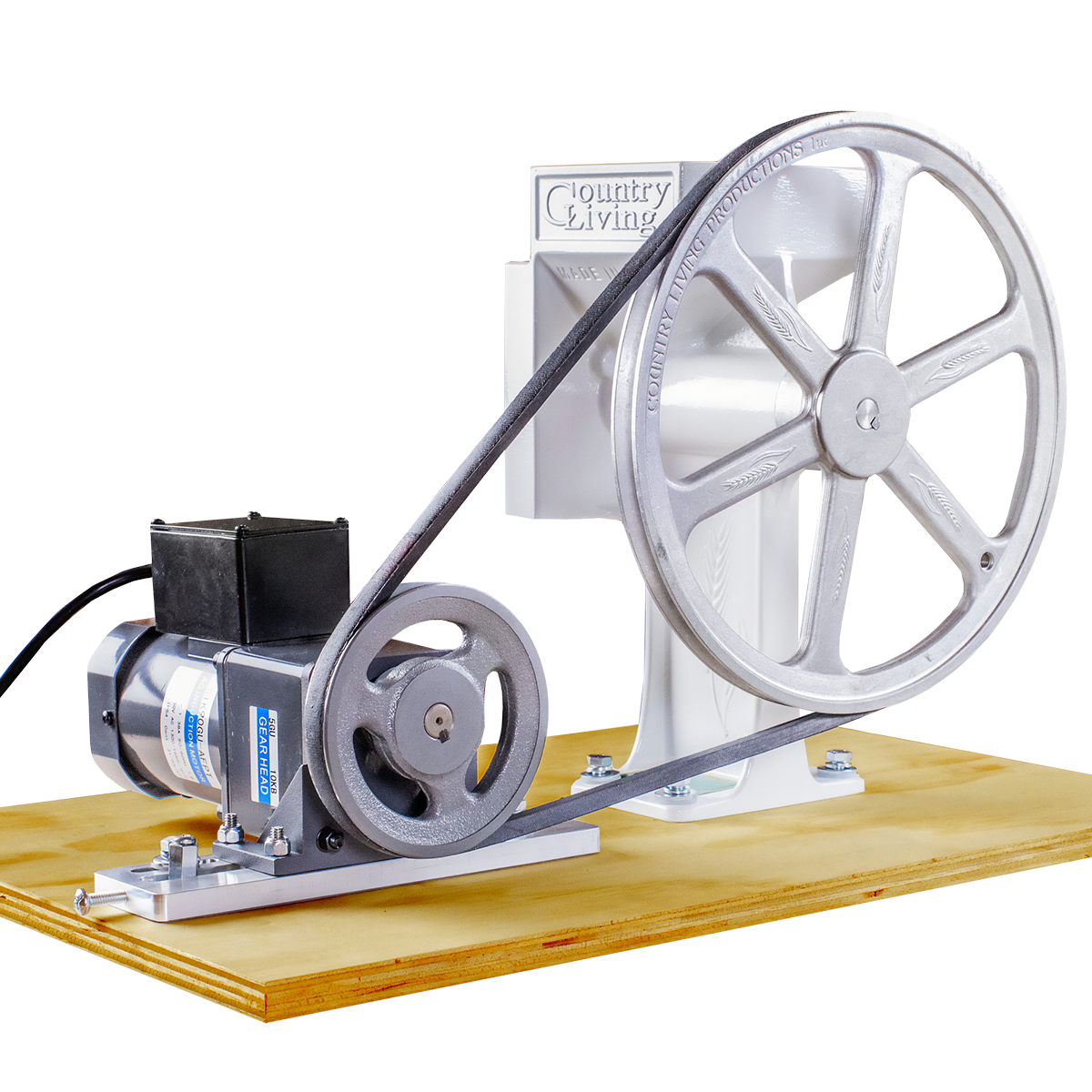

Purchasing our Motorization Kit is the easiest way to motorize your Country Living Mill.

Our motorization kit has a gear reduction motor attached to a plywood base. It comes with a safety guard to hide the pulley wheels and belt. The board is pre-drilled and pre-threaded. All you have to do is bolt your Country Living Mill to the board, attach the belt and belt guard, tension the belt and it's ready to go. Just like the Country Living Mill, the motorization kit is built to last for many years. With this kit, your mill turns at about 65 to 75 rpm to ensure a cool grind for all your flours.

Our motorization kit has a gear reduction motor attached to a plywood base. It comes with a safety guard to hide the pulley wheels and belt. The board is pre-drilled and pre-threaded. All you have to do is bolt your Country Living Mill to the board, attach the belt and belt guard, tension the belt and it's ready to go. Just like the Country Living Mill, the motorization kit is built to last for many years. With this kit, your mill turns at about 65 to 75 rpm to ensure a cool grind for all your flours.

On the right, you'll see our motorization kit with and without the safety guard. As long as you have electricity this is a wonderful way to grind your flour. It's quiet (you can actually have a conversation standing next to it), and the grind is very cool. We've had our motorization kit on the Country Living Grain Mill for over ten years, and ground flour for friends, neighbors, and a large extended family. There has been minimal wear on the grinding plates, and the motor has performed flawlessly. In short, we love it.

Creating Your Own Motorization Kit

Many mechanically-inclined owners of the Country Living Grain Mill have decided to motorize their own mills. If you are interested in motorizing your Country Living Mill we have listed some guidelines below.

Many mechanically-inclined owners of the Country Living Grain Mill have decided to motorize their own mills. If you are interested in motorizing your Country Living Mill we have listed some guidelines below.

For high speed motors the preferred methods for motorizing your Country Living Grain Mill involve the use of intermediate pulleys, which are the key to reducing the milling speed. Thus giving you cooler more nutritious flour. This also minimizes the wear on your Country Living grinding plates and bearings.

Gear-reduced Motors

For those who don't want to mess with intermediate pulleys we offer a gear reduced motor. This is the exact same motor which we use on our own motorization kits, and it is already geared down to run your Country Living grain mill at its recommended speed.

Pulleys

Additionally we carry the 4.9" pulley for this motor (or other motors with a 5/8 inch shaft).

This is an AK51 5/8" pulley with v-groove.

Schematics For Motors Which Require An Intermediate Pulley

Schematics For Motors Which Require An Intermediate Pulley

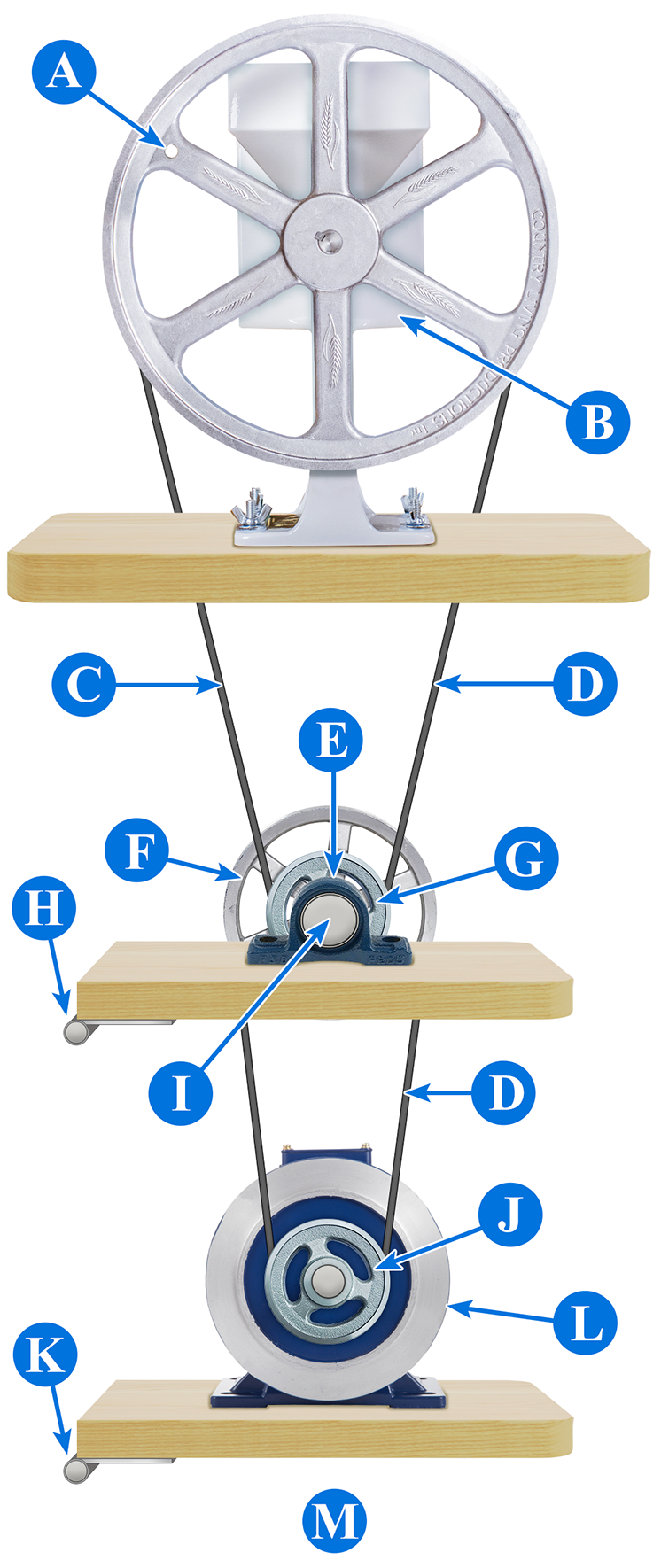

Vertical Installation

A. Always remove handle when motorizing your mill.

B. Country Living Grain Mill

C. Note: Belts and pulleys should be enclosed for safety reasons.

D. Size A or 4L V-belt 1/2" wide X 5/16" thick.

E. 5/8" keyed shaft.

F. 6" pulley

G. 2" pulley

H. Pivot

I. 2 ea. 5/8" pillow block bearings

J. 2" pulley

K. Pivot

L. 1750 RPM washer or drier motor

M. Weight of motor will keep belts tight.

This set up runs at 97 rpm

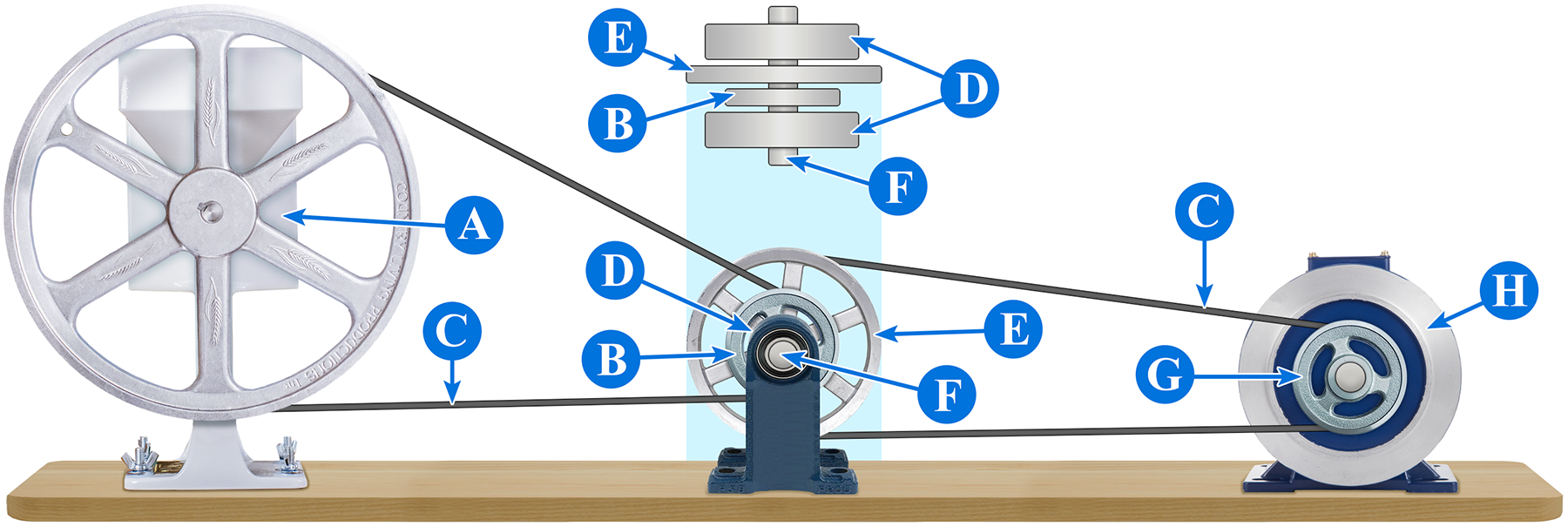

A. Country Living Mill

B. 2" Pulley

C. Size A or 4L V-belt 1/2" wide X 5/16" thick

D. 5/8" pillow block bearings

E. 6" Pulley

F. 5/8" Keyed Shaft

G. 2" Pulley

H.1750 RPM washer or dryer motor

This set up runs at 97 rpm The following formula will allow you to compute the pulley size needed to achieve a specific RPM:

Driven Pulley Size X Speed of Driven Pulley / by Speed of Driving Pulley = Size of Driving Pulley

120 is the absolute maximum RPM for the Country Living Grain Mill. Through long experience, we have discovered that our mill performs optimally at revolutions of less than 75 per minute. The flywheel of the Country Living Grain Mill has a 12" diameter.

The Easiest Method:

The 1150 RPM Motor with no intermediate gear reduction.

If you are not mechanically inclined, and want to go a simpler route, some people use the 1150 RPM motor because they are readily available. This set up runs at 143 rpm; we at Country Living feel that this is still too fast because it heats up and creates wear on your plates. However, many people have done this because it is the simplest and quickest way to motorize your mill.

We personally recommend that you grind the flour slower and cooler, and have shown you, with the schematics and formula above, how to do this.

Motorizing with a 1150 RPM motor

A. Always remove handle when motorizing your mill.

B. The Country Living Mill

C. Size A or 4L V-belt 1/2" wide X 5/16" thick. Belts and pulleys should be enclosed for safety reasons.

D. The Motor. Must be a 1150 RPM slow turning motor. If you get slots in the motor mounts, this will make it a lot easier to get the correct tension on the belt during installation.

E. Motor Pulley: 1-1/2" diameter.

F. Slidable mounting block for setting the belt tension. You can skip this if you purchased a motor with slots in the mounts.

Robert Dee's Mill Motorization GuideLines:

One Country Living Mill owner, Robert Dee, put together a motorized mill and kindly shared his photos and technical specifications with us.

He purchased the motor from a surplus center. The 2 Horse Power motor was originally used for a tread mill, and has a soft start- which means it takes about five-seconds time for the motor to build up to full speed.

This motor is rated at 1,800 rpm (Revolutions per Minute), which would turn the Country Living Mill far faster than we recommend- in fact, it just might send your grain mill into orbit.

Robert solved this problem by gearing the speed down with an intermediate 6" pulley linked with a 1 3/4" pulley that ties to the 12" flywheel of the grain mill.

Robert solved this problem by gearing the speed down with an intermediate 6" pulley linked with a 1 3/4" pulley that ties to the 12" flywheel of the grain mill.

A. 12" Flywheel

B. 6" Pulley

C. 1 3/4" Pulley

D. 1 1/2" Pulley

E. Motor

Not satisfied with off the shelf parts, Robert re-machined one pulley he purchased so that it was very concentric, within .002 inches, and then made his own pulleys for the motor and idler shaft! The total drive ratio is about 27-1/2 to 1.

Though the mill has a variable speed adjustment, Robert runs the mill at about 60 rpm, which he feels is the highest speed he can use without overheating the grain.

There's a reason Robert has put together one of the most impressive home-built motorization kits we've ever seen. Apparently Robert is no amateur. For years he has designed embedded microcontroller circuits and has several medical instrument patents to his name. The Tach-Plus is an instrument he designed to measure rpm, and this is what he used to determine the speed of the mill.